testing hardness|hardness tester for thin material : tv shopping Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most . Resultado da The fastest way to access mobile apps in the workplace. Try our online demo to familiarise yourself with our product, or contact our sales team to learn more. Instantly run mobile .

{plog:ftitle_list}

Resultado da Como instalar o Pin Up Casino no Android. O aplicativo pode ser instalado da seguinte forma: Baixe o Pin Up Casino Apk pelo site oficial da empresa; .

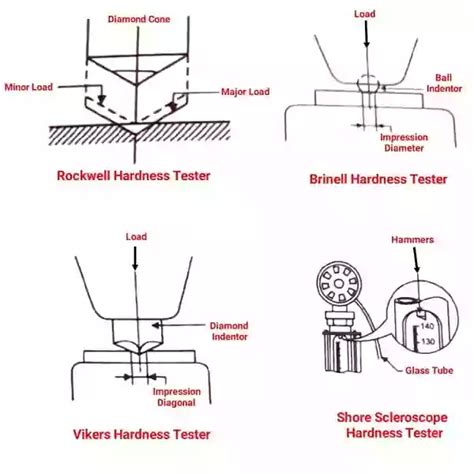

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by .Hardness Testing Basics. Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the .

The Mohs Hardness Scale is a widely recognized and simple scale for measuring the scratch resistance of various minerals. Created by Friedrich Mohs, a German geologist, in 1812, it remains a standard in geology, .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed.Learn more about hardness testing and see our full range of hardness testers on www.hardnesstesters.com. Learn about considerations, sample sizes, sample thickness, .

What is suitable when? If you need a quick, non-destructive measurement for a variety of materials in a manufacturing setting – the Rockwell hardness test is suitable. For softer materials or materials with coarse microstructures – the .

Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. Various hardness testing . Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel .The Knoop hardness test method is one of microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. The Knoop .

🧴Method 1: Simple Soap Test. The soap test is a great way to determine water hardness.It won’t tell you exactly how hard or soft your water is, but it’s a quick and easy indicator of whether or not you have hard water.. You .In hardness testing, there are inherent variables that preclude using standard Gage R&R procedures and formulas with actual test pieces. Material variation and the inability to retest the same area on depth measuring testers are two significant factors that affect GR&R results. Hardness testing methods vary based on the material and heat treatment chosen. It’s important that engineers specify hardness testing methods correctly to ensure timely heat treatment and avoid costly delays. Common hardness testing methods are introduced below. Rockwell Hardness

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .Hardness testing of welds can be performed on any Vickers micro hardness testing machine. When hardness testing of welds, a series of measurements are made in a given pattern at a specific distance from the sample edge or top of the weld. The progression of the hardness values can then be plotted in a graph.

ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors caused by the .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and . The Mohs hardness scale rates the hardness of minerals based on their ability to scratch softer ones. The Mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer minerals. The scale isn’t perfect, but it’s a great tool for quick identification of rocks in the field.The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is useful for a variety of applications such as: testing very thin materials like foils or measuring the surface .Hardness Testing Methods Rockwell Test Method, as defined in ASTM E-18, is the most commonly used hardness test method. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods.

Brinell Hardness Test. You might have heard about this in school, that you can get a ball bearing, whack it with a hammer on a piece of metal with a known hardness, then whack it on the piece of metal in question, compare the . Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, . In scientific terms, water hardness is generally the amount of dissolved calcium and magnesium in water. But in layman's terms, you may notice water hardness when your hands still feel slimy after washing with soap and water, or when your drinking glasses at home become less than crystal clear. Learn a lot more about water hardness on the Water Science .

Different main loads (test forces) will be used in hardness testing, depending on the required application. Conditional on the size of the main load applied to a specimen when conducting the hardness test, differentiation is made between micro, low-load, or macro hardness testing within ISO standards. Image Credit: ZwickRoell GmbH Co. KGMohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material.. The scale was introduced in 1812 by the German geologist and mineralogist . How to Test Water Hardness. There are 4 effective methods for testing water hardness: Checking with your water supplier; Running a soap buds test; Ordering water testing kits online; Sending a water sample to a certified water testing lab; Let’s take a close look at each method. 1. Checking With Your Water Supplier

Online Article: “Hardness Testing: A Comprehensive Guide” – Buehler. Source: Buehler; Summary/Annotation: This article from Buehler provides an in-depth overview of hardness testing, discussing different methods such as Rockwell, Vickers, Brinell, and Knoop hardness tests. It explains the principles behind each method, the types of .Hardness testing on metals is used to evaluate the resistance of a metal to deformation or permanent damage, specifically in terms of indentations or scratching. It involves applying a consistent force using a rounded or pointed object under controlled conditions to create a small dent on the surface of a metal. The size of the dent is then .

The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of the indentation as the force on the .Mohs hardness, rough measure of the resistance of a smooth surface to scratching or abrasion, expressed in terms of a scale devised (1812) by the German mineralogist Friedrich Mohs. . the test may only loosen grains without testing individual mineral surfaces; thus, certain textures or aggregate forms may hinder or prevent a true hardness .Knoop is an alternative to Vickers in the micro hardness testing range. It is mainly used for brittle materials and to facilitate the hardness testing of thin layers. The indenter is an asymmetrical pyramidal diamond, and the indent is measured by optically measuring the long diagonal.The Janka hardness test (English: / ˈ dʒ æ ŋ k ə /; [1] German:), created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. [citation needed] It measures the force required to embed an 11.28-millimeter-diameter (7 ⁄ 16 in) steel ball halfway into a sample of wood.(The diameter was chosen to .

The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .

types of hardness testing methods

types of hardness testing machine

hardness testing techniques

Microsoft Search empowers people to find the information they need by unlocking knowledge and expertise. Integrated with Microsoft 365. Microsoft Search is a .

testing hardness|hardness tester for thin material